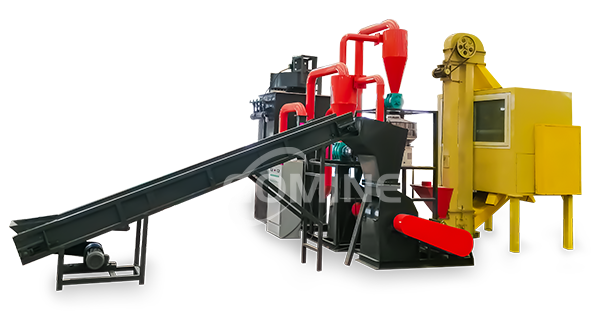

Our circuit boards recycling machine adopts advanced physical recycling process, which can help you obtain metal, resin powder and fiber powder from used printed circuit boards. Copper powder and resin fiber powder can be sold directly in the market, therefore, recycling pcbs can not only bring great economic value, but also protect the environment

The processing process of PCB recycling machine

Step 1: Electronic components dismantling

Usually, the first step of circuit board recycling is to separate the electronic components from the circuit boards by using PCB dismantling machine. Then you will get naked circuit mother boards, which will get further processing to get copper powder and resin powder.

Step 2: PCB boards shredding and crushing

Circuit board shredder is the very first machine to size reduce circuit board. Its infeed opening should be big enough to process tons of circuit board at the same time. During shearing and crushing of 2 rotors, circuit boards are broken down into irregular pieces. For the first shredding machine, we choose the double shaft shredder. After circuit board shredding, the particles are around 60mm by 60mm. Next, the second crushing machine is a granulator, resulting in 20mm particles. Then the shredded material is collected in a mesh box and processed further.

Step 3: Separate the metal and non-metal powder

The shredded PCB will be separated by the air separator and the electrostatic separator. Our PCB recycling machine adopts dry type and physical crushing, separation and dedusting methods, which can keep no pollution to the environment. And the high pressure electrostatic separation combined with air separation process, which can purify approximately 99% metal powder.

Features of our pcb circuit board recycling machine

- High rate of metal recovery

- Saving power,saving manpower

- Electricity choose separation efficiency is as high as 99.9%, finished products can be directly put on the market.

- No pollution, due to the pulse dust removal equipment.

- High purity rate of end-pure copper as high as 97%.

- PLC system makes it easier to control the whole line, the negative pressure feeding system prevents the dust from running out

Technical parameter of circuit board recycling machine

| Model | Power (kw) | Recovery percent (%) | Collection coefficient (%) | Output (kg/h) | External Dimension (mm) | Weight (kg) |

| GMP-1000 | 45 | ≧98 | ≧99 | 150-200 | 6000*7500*4200 | 4250 |

| GMP-1500 | 68 | ≧98 | ≧99 | 200-300 | 7000*8200*4500 | 6500 |

| GMP-1800 | 110 | ≧98 | ≧99 | 300-500 | 8000*11000*4800 | 8500 |

| GMP-2000 | 198 | ≧98 | ≧99 | 1000-1200 | 8200*16000*5250 | 12500 |

We are experts in the field of solid waste recycling especially metal recycling. We can provide a complete set of solutions, including waste cable recycling, waste circuit board recycling, metal and non-metal crushing and sorting, mixed plastic recycling, etc. If you have any need of our machine, feel free to contact Gomine Machinery.