Aluminum composite panels consist of three layers: a plastic core sandwiched between two aluminum layers. These panels are commonly used in building decoration and generate a significant amount of waste. However, the aluminum layers have high recycling value, making recycling economically viable.

Traditionally, aluminum recycling from ACPs involved manually opening the end of the panel and peeling off the aluminum. Because the composite process of the ACP panel is made of high-temperature thermal compounding, the ACP separator machine can separate the aluminum and plastic after heating to a preset temperature.

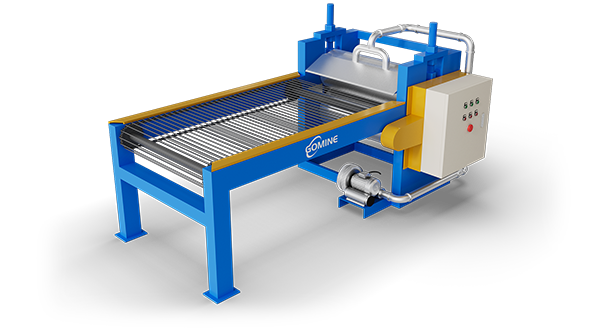

The scrap ACP separator machine comprises various components including a peeling mechanism, a discharging mechanism, rollers, sprockets, and a power mechanism consisting of a motor and gearbox. The motor drives the gearbox via a belt, ensuring stable operation of the machine.

As the demand for aluminum and plastic sheets increases, so does the need for efficient processing and recycling methods. The ACP stripping machine offers several advantages: it is easy to operate, generates minimal pollution and noise, and boasts high efficiency. Moreover, it utilizes dry physical separation, preventing secondary environmental pollution and providing significant social and economic benefits.

In summary, the ACP sheet stripping machine plays a crucial role in the recycling industry by efficiently separating aluminum and plastic layers from composite panels, contributing to resource conservation and environmental protection.

We are experts in the field of solid waste recycling especially metal recycling. We can provide a complete set of solutions, including waste cable recycling, waste circuit board recycling, metal and non-metal crushing and sorting, mixed plastic recycling, etc. If you have any need of our machine, feel free to contact Gomine Machinery.