Large scale radiator recycling line is different from the average radiator recycling plant in the market, which was designed for all kinds of radiators from air conditioning, car, and water tank.

The whole radiator recycling line adopts dry type physical separation technology. It can recycling aluminum, copper and iron from waste radiators efficiently by shredding, air separation and magnetic separation process. This copper aluminum radiator recycling machine has no much limit for the input materials, any damaged or deformed radiators and electronic rotors less than 16cm could be directly processed.

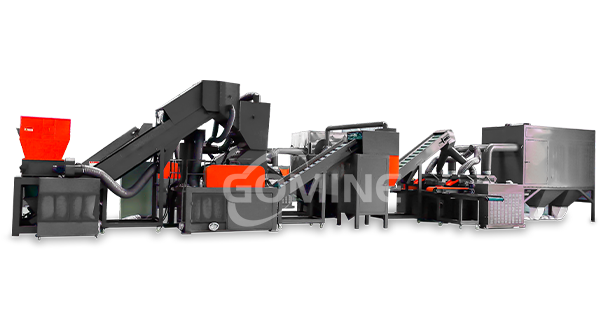

The main parts of commerical radiator recycling line

1. Primary crusher (double shaft shredder)

To crush scrap radiators to 10-20mm pieces, then the crushed material is transported by the conveyor to the second crusher. Double shaft shredder has been proved to be the most efficience machine for metal recycling.

2. Secondary crusher

After transported to this crusher, the 10-20mm material is shredded by this crusher to smaller pieces.

3. Magnetic Separator

To separate iron from copper and aluminum, so that copper and aluminum can be separated easily.

4. Vibrating Separator

To separate copper pieces from aluminum pieces.

5. Pulse dust collector

Effectively reduce the dust generated in the production process and ensure a clean working environment.

Why choose our radiator recycling equipments ?

- We try to reduce the number of times materials being crushed, thereby reducing the generation of metal powder to improve recycling efficiency.

- The primary shredding adopts large torque double-shaft shredder, both the blades and shaft are alloy material with special treatment, firm and durable.

- Safe and reliable structure, strong processing capacity, stable operation.

- Using twice gravity separation, which improve the sorting accuracy.Sorting out of copper, aluminum, iron purity > 99%.

- Due to the high separation rate of the machine, it can save a lot of staffing.

Technical parameter of radiator recycling machine

| Model | Power(kw) | Capacity(kg/h) | Purity(%) | Dimension(m) | Weight(kg) |

| GMCA-800 | 95 | 800-1000 | 99 | 14.8*3.8*4.2 | 8500 |

| GMCA-1000 | 135 | 1200-1500 | 99 | 16.8*3.8*4.5 | 10500 |

We are experts in the field of solid waste recycling especially metal recycling. We can provide a complete set of solutions, including waste cable recycling, waste circuit board recycling, metal and non-metal crushing and sorting, mixed plastic recycling, etc. If you have any need of our machine, feel free to contact Gomine Machinery.