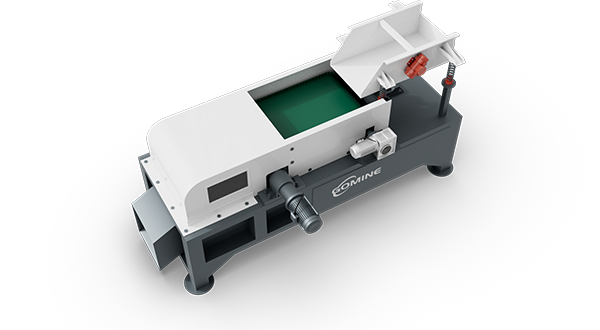

Working principle of eddy current separator

Eddy current separators remove nonferrous metals such as aluminum, die-cast metal, and copper from nonmetallic material.

When a piece of nonferrous metal, such as aluminum, passes over the separator, the magnets inside the shell rotate past the aluminum at high speed. This forms eddy currents in the aluminum, which in turn create a magnetic field around the piece of aluminum. The polarity of that magnetic field is the same as the rotating magnet, causing the aluminum to be repelled away from the magnet. This repulsion makes the trajectory of the aluminum greater than that of the nonmetallics, allowing the two material streams to be separated.

Application of eddy current separator

The eddy current sorting equipment is particularly suitable for the separation between high-conductivity and low-density substances and low-conductivity and high-density substances, and between conductors and non-conductors. Ferromagnetic substances cause high heat damage to equipment due to eddy currents. The processing objects of eddy current sorting are scrap copper (aluminum) power cables, aluminum products, automotive scrap, non-ferrous metal debris, printed circuit board gray ballast, non-ferrous metal-containing glass ballast, electronic waste, polymetal (Al, Cu , Pb, Zn) mixture, cast copper (aluminum) sand and ballast.

The main application industries of eddy current include: electronic waste recycling, municipal solid waste treatment, treatment of industrial solid waste, and purification of molding sand in aluminum and non-ferrous metal casting industry.

Advantage of our eddy current sorting machine

- Easy to operate, automatic separation of metal from non-metallic.

- Large range feeding materials, normally 3-100mm.

- Easy to install, low energy consumption, easy maintenance

- Variety rotor designs are available.

- High yields of non-ferrous metals recovery

Technical parameter of eddy current separator

| Model | Belt Width (mm) | Power (kw) | Capacity (m3/h) | Dimension (mm) |

| GMEC-40 | 400 | 3.7 | 1-2 | 2200 x 1600 x 1200 |

| GMEC-60 | 650 | 4.0 | 6 | 2250 x 1750 x 1075 |

| GMEC-80 | 800 | 5.5 | 7.5 | 2360 x 1960 x 1110 |

| GMEC-100 | 1000 | 5.5 | 9 | 2470 x 2200 x 1140 |

| GMEC-120 | 1200 | 7.5 | 12 | 2560 x 2450 x 1180 |

We are experts in the field of solid waste recycling especially metal recycling. We can provide a complete set of solutions, including waste cable recycling, waste circuit board recycling, metal and non-metal crushing and sorting, mixed plastic recycling, etc. If you have any need of our machine, feel free to contact Gomine Machinery.