The rubber, steel wire, fiber, carbon black, oil and gas contained in waste tires have high recycling value. Through effective recycling, these materials can be put back into production, reducing resource waste, protecting the environment, and achieving both economic and ecological benefits.

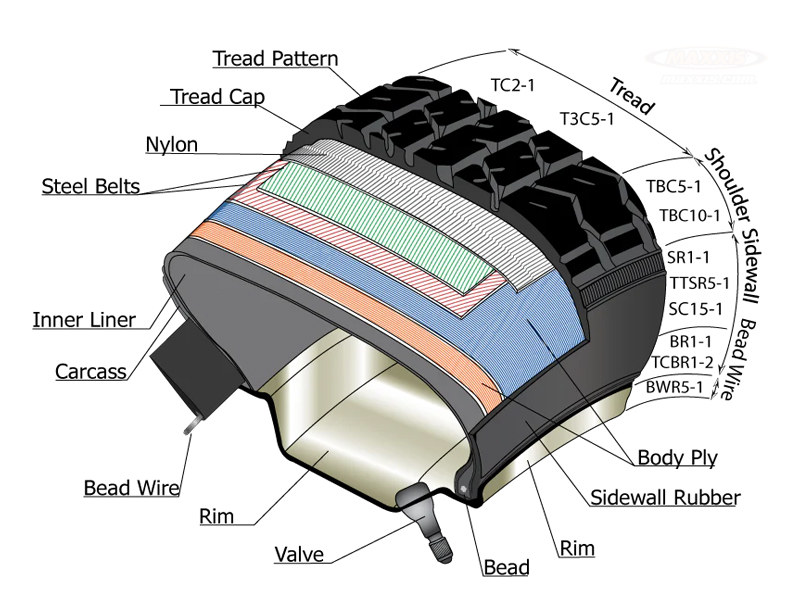

1. Rubber: Rubber is the main component of tires, accounting for about 60% of the total weight of tires.

2. Steel Wire: Tires usually contain steel wires, which are used to strengthen the structure and durability of the tire. Steel wires account for about 15% of the tire's weight.

3. Fiber: The tire also contains a certain amount of fiber material, which is used to increase the strength and wear resistance of the tire. The fiber accounts for about 5-10% of the tire weight.

4. Carbon Black: Carbon black is a filler and reinforcement used in tires, making up about 20% of the tire's weight.

5. Oil and Gas: Through thermal cracking technology, waste tires can be decomposed into oil gas, carbon black and steel wire.

Due to the different types and sizes of tires, the machines used in the tire recycling production line will also be different. But no matter car tires, truck tires, tractor tires, trailer tires, off road tires (OTR) and other types tires, GOMINE can always provide you with the most suitable solution.

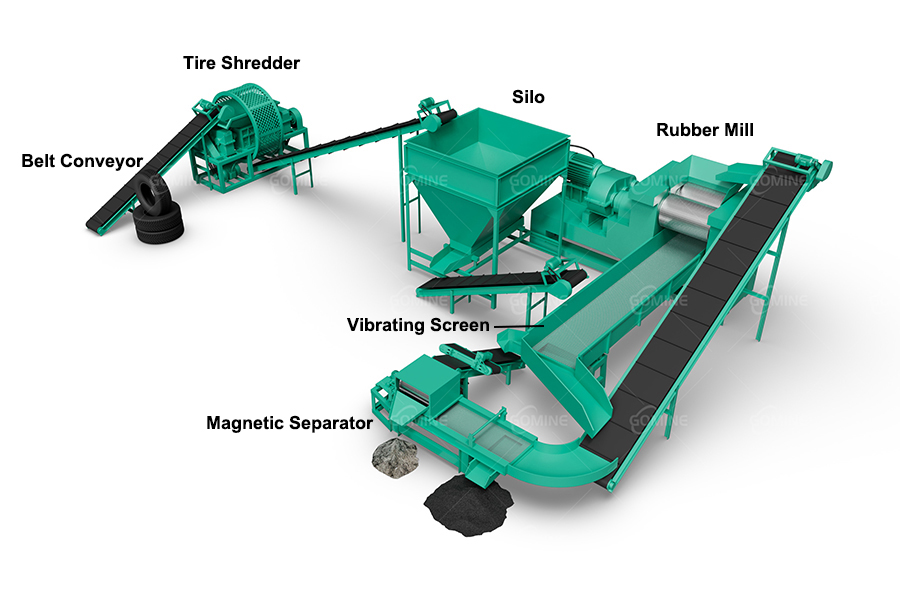

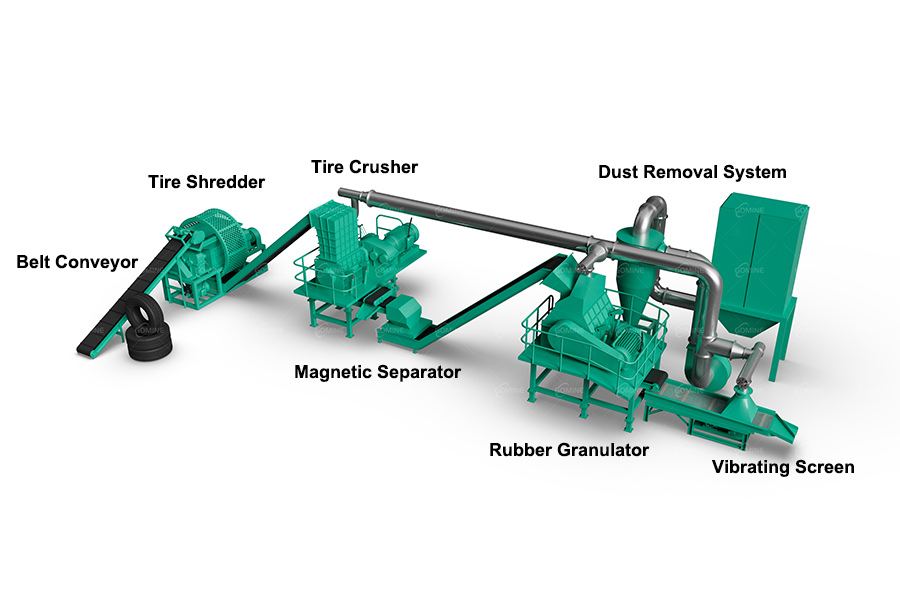

In this page, we share you with two of our solutions for tyre recycling: tire rubber powder production line and tire rubber granules production line. The machines and capacity of the entire production line can be adjusted according to your needs. Don't hesitate to contact us if you need customized solution.

The tire rubber powder production line operates at room temperature. It can achieve tire crushing, tire wire separation, fiber separation, and tire powder making at one time. During the process, no wastewater, waste gas, or dust is generated, which meets environmental protection requirements. It can produce fine rubber powder below 30 meshes. The size of the rubber powder can be customized into different meshes according to demand. After the rubber powder is restored, it can replace natural rubber to make thousands of rubber products.

Cut off the tire sidewall.

Put the tire onto the cylinder and automatically cut it into strips for the next step of crushing.

The tire recycling line will be equipped with several belt conveyors to automatically transport tire materials according to demand.

Shred tire strips into small rubber pieces.

Store the shredded tire rubber pieces and feed them to the next step.

Two rollers squeeze and grind the tire rubber pieces into rubber powder between 10-100 mesh. The fineness of the rubber powder is adjustable.

The vibrating screen can transfer the tire rubber that does not meet the size to the rubber mill for grinding again. Repeat this step until the rubber powder meets the required size.

Completely separate the steel wire capillaries in the rubber powder.

Cool down to ensure the machine can operate normally for a long time, cool down the rubber powder and pack it in bags.

Collect dust and fibers generated by the tire rubber powder production line.

Waste tires can be recycled into rubber granules. Waste tires are crushed, ground into small pieces and screened to make clean, uniform-sized, high-quality rubber granules. Rubber granules of different specifications can be produced and customized according to customer needs. The production line uses physical methods to operate at room temperature and will not produce secondary pollution. Rubber granules made from waste tires can be used in rubber floors, playgrounds, runways, basketball courts, gyms, amusement parks and other places that require shock absorption, noise reduction and anti-slip.

Pull out the steel wire on the sidewall of the tire in one go and separate the steel wire and rubber smoothly.

The tire recycling line will be equipped with several belt conveyors to automatically transport tire materials according to demand.

Primary crushing to tear the tire into rubber blocks.

Secondary crushing to crush the tire rubber blocks into 10-50mm rubber crumbs.

Separate the steel wire capillaries in the rubber pieces.

Make tire rubber fragments into rubber granules of uniform size of 0-6mm. During the tire granulation process, 99% of the fibers are removed, leaving clean rubber particles.

There are three layers of screens, which can obtain rubber particles of sizes of 0-1mm, 1-3mm, and 3-6mm respectively. The screen size can be customized according to customer needs to obtain rubber particles of different specifications.

Collect dust and fibers generated by the tire rubber granules production line.

Thanks for your interest in Gomine Recycling Machinery. If you want to learn more about our solid waste shredder machines, Contact Us Now!

Copyright © Gomine Environmental Protection Technology Co., Ltd. All Rights Reserved